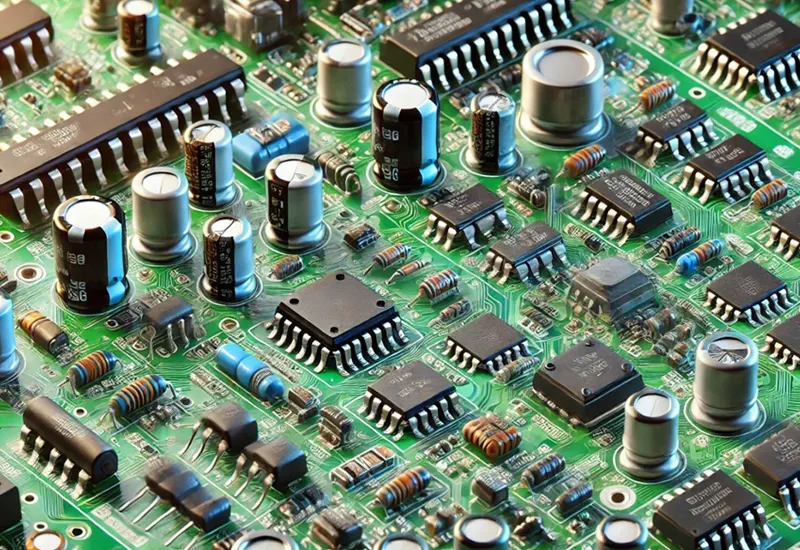

We specialize in both SMT (automated high-speed mounting of components) and Through-Hole Assembly. Our flexible line setup allows us to handle mixed-technology boards and various component sizes with high accuracy.

Prototype & Mass Production

We work closely with engineers and innovators to turn ideas into functional prototypes. Our rapid prototyping services help you test and validate designs quickly, with expert feedback and small-batch flexibility.

Component Sourcing & Procurement

Our team sources components from trusted global suppliers to ensure quality, cost-effectiveness, and timely availability. We manage the entire procurement process and offer alternatives for hard-to-find or obsolete parts.

PCB Design & Engineering Support

Need help refining your design? We offer assistance with DFM (Design for Manufacturing) and DFT (Design for Testing) to improve manufacturability and reduce costs. Our engineers collaborate with your team to ensure seamless transition from design to production.

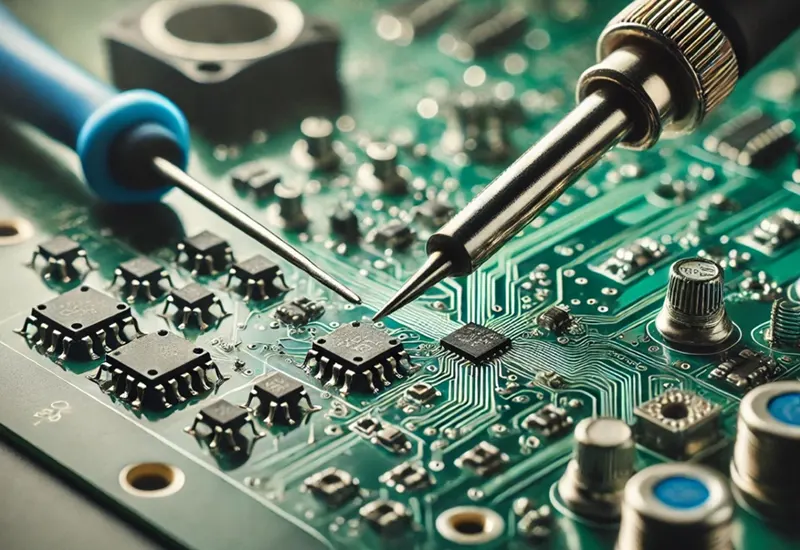

Testing & Quality Assurance

Every PCB that leaves our facility is tested for functionality and build quality. Our quality control process includes Automated Optical Inspection (AOI), manual visual checks, and functional testing (as required) to detect and prevent issues before final delivery.

Box Build & Final Product Assembly

We offer complete box build services, including enclosure assembly, cable harnessing, labeling, and packaging. This means we can deliver fully assembled, tested, and ready-to-ship products — saving you time and overhead.